Understand what S&OP is and how to successfully implement it to make planning more effective, resulting in reduced operating costs and an increased service level

In an increasingly competitive and rapidly changing market, an important practice adopted by companies for maintaining a competitive advantage is S&OP – Sales and Operations Planning.

Originating in the late 1980’s, it has become a strategic tool for companies, and not just a medium and long-term production plan. These days, having a flexible S&OP is a key factor for companies in being resilient to changing environments, providing increased service levels and reduced inventories. In this way, the implementation of the S&OP can increase revenue, reduce the company’s costs, and leverage the marketing performance of products.

What is S&OP?

In general terms, S&OP can be understood as a series of decision-making processes that, supported by mathematical models and quantitative analyses, aim to:

- Balance supply and demand

- Integrate the financial plan into the operational plan

In other words, it is, basically, a continuous planning process through which the company aligns the production plan with the sales plan. It is responsible for maintaining consistency between the company’s strategy and its operation by interconnecting plans at the strategic, tactical, and operational levels.

The S&OP integrates different areas, such as Operations, Logistics, Sales, and Finance so that, together, they define the best plan for supply and demand. Moreover, it has the support of senior management, who are responsible for giving the final word.

One thing companies misunderstand is that S&OP is limited to systems, when in reality, it is planning structured with the alignment of the different areas involved, while systems merely support it.

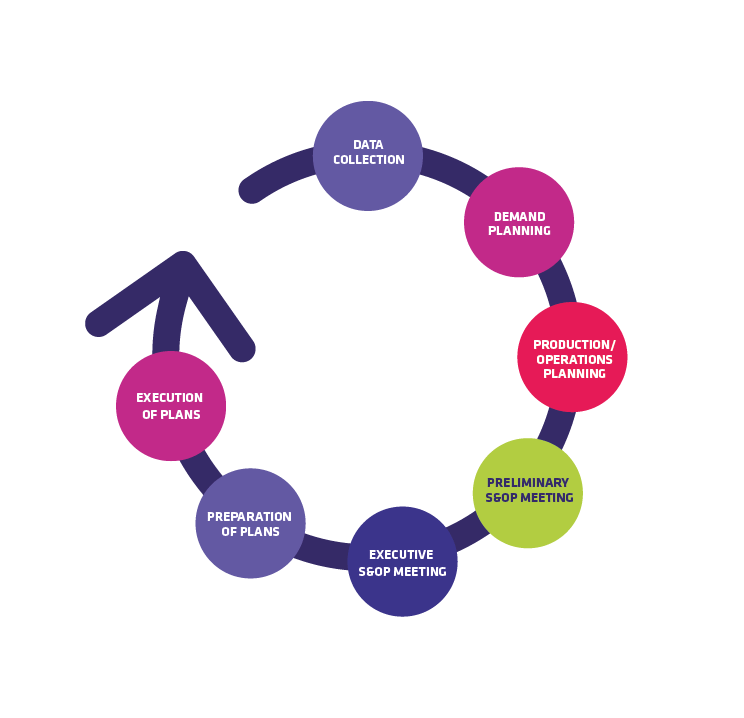

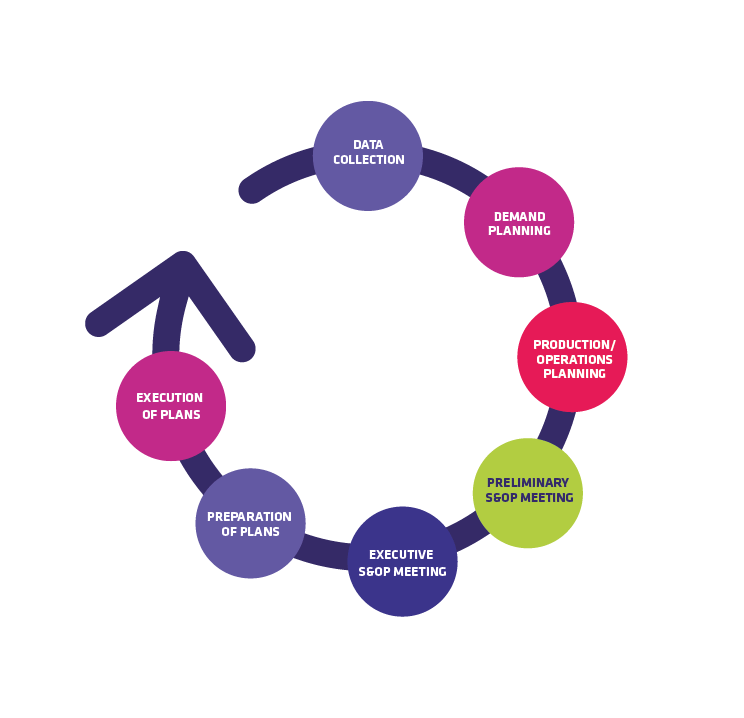

The S&OP is a cyclical process, periodically repeated and comprising seven steps, beginning with data collection to forecast demand and ending in the execution of sales and operations plans.

Thus, it contributes to reducing conflicts between the different areas involved, managing bottlenecks and commercial / operational restrictions, and integrating plans to the budget process.

Implementing S&OP

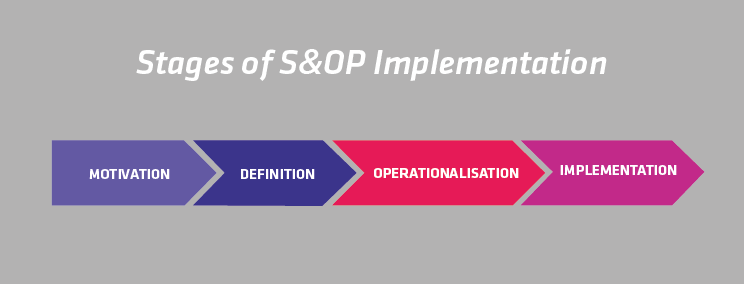

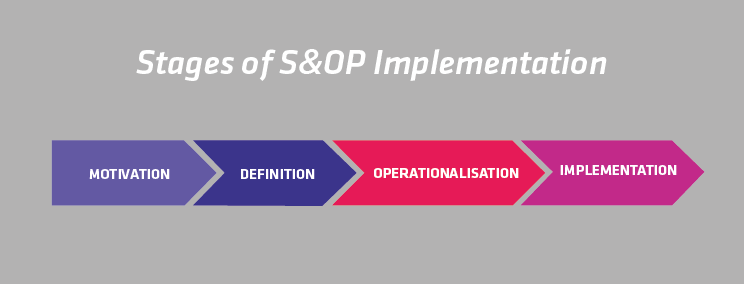

The S&OP implementation process can be structured in four phases: motivation, definition, operationalisation, and implementation. It can be carried out in partnership with consultants or developed in-house, in any case requiring a dedicated team. Generally speaking, the main costs involved are labour costs and possible acquisition of systems.

1. Motivation

The first step consists of understanding the motivators of S&OP implementation in the company. It is essential to diagnose the current situation in order to understand the existing planning process and its main gaps. In this way, the future process can be designed and implemented in a manner suited to the company’s reality and to the expectations of senior management.

The main motivators for S&OP implementation are the need for:

- Preparing a plan suited to the company’s reality;

- Managing change efficiently and effectively;

- Inventory management and more effective capacity;

- Performance evaluation;

- Integration of the areas involved in planning.

2. Definition

Once the goals of the S&OP are understood in the company, it is necessary to design a model that will most effectively tackle the organisation’s planning gaps. Thus, more comprehensive decisions are made at this stage, such as product families, the degree of detail with which each will be treated, and mathematical models to be used.

3. Operationalisation

This step defines how the S&OP will be operationalised, i.e., this step establishes:

- Those responsible for the process, such as leaders; pre-S&OP, demand planning, area planning, and executive S&OP teams.

- The report templates that will be generated, such as operations reports, logistics reports, and sales reports, among others.

The KPIs that will be calculated, such as sales forecasting indicators (MAPE, MAD, ME), inventory indicators (Turnover, Coverage, Service Level), among others.

Learn more: KPIs

ME: Indicates the error of the forecast compared to the actual. Since errors can be positive or negative, on average they cancel each other out, giving the false impression that the error is low.

MAD: Indicates the magnitude of the forecasting error compared to the actual as an absolute number.

MAPE: Indicates the magnitude of the forecasting error compared to the actual as an absolute percentage

Turnover: Indicates the number of times (speed) a product’s inventory is replenished during a certain period.

Coverage: Indicates the amount of time (in days, weeks, or months) the existing inventory would take to be fully consumed if it was not going to be replenished.

Service Level: Measures the odds of stockout not occurring, i.e. how much your demand is being met. There are different ways to calculate the service level, such as type 1 (α), which measures the frequency at which demand is completely met and type 2 (β – Fill Rate), which measures how much of your demand is being met.

- The systems used to follow up the process, such as the planning consolidation system, KPI monitoring system, and the financial follow-up system for the process.

- The S&OP procedures, including the annual timetable and review schedule.

4. Implementation

Finally, the last step consists of preparing and executing the S&OP process implementation plan. As in any implementation of a new process, this step requires significant effort in managing change. It is necessary to engage all those involved, and have the support of senior management. A sponsor, who views the transition as a whole, such as a CEO, is critical to the success of the implementation.

Key Factors for Success

The success of the S&OP and obtaining the expected results mainly depend on three key points:

- Governance/Processes

- People

- Technology

In addition, it is necessary to have goals clearly defined and aligned with the company strategy, and conduct constant follow-up to identify points of improvement.

Bear in mind that, in order to adopt this practice, there is no need to invest heavily in systems and/or very complex processes at the outset. It is possible to begin implementing S&OP with simple spreadsheets and gradually implementing more robust technologies as processes mature.

The most important thing is to have the support of leadership and a motivated team. Budgetary issues should not be an obstacle to implementation, since the initial benefits can be obtained from simpler S&OP practices.

Thus, S&OP implementation is becoming increasingly common, both by product and services companies, and consolidating as a powerful trend in the market.

About the authors

Ana Pantaleão is a Visagio consultant specialising in; logistics, supply chain, and operations, with a focus in operations and support in the retail, banking, oil & gas, and mining sectors, among others. Ana holds a Master’s Degree in Supply Chain Management and Optimisation from Écoles des Mines de Nantes.